We are honored to partner with Ratera for the distribution of braiding machines, and Metag for narrow fabric looms.

All machinery projects are reviewed by Fletcher and any partnering company engineers to assure our customers of the best manufacturing solution.

We provide spares support from our extensive inventory of parts in addition to our in-house electronic and mechanical technicians. They are available by phone or on-site to train, troubleshoot, and advise best practices.

We offer Ratera braiding machinery for the efficient manufacture of braided rope, cords, over-braid, and medical structures. We back all installations with the highest level of customer spares service and technical support.

Ratera offers a wide range of automatic and semi-automatic winders to suit every bobbin winding task.

ML-100: the latest in automatic winding technology, the ML-100 adjusts winding speed, traverse length and speed and and bobbin size to accommodate multiple bobbin types on one machine. Parameters are saved as recipes for instant recall to wind new fibers or bobbins instantly.

PVLU: our most popular, the PVLU series is available in 220 through 650 mm traverse lengths. A semi-automatic machine, the PVLU is the best solution for weaving quills and braider applications from 140 through 727 mm gauge machines

Take-ups: Ratera builds the best in machine mounted and autonomous take-ups. Available for all machines, Ratera take-ups feature simple set-up, easy loading and for autonomous units mobility between machines.

We provide spares support from our extensive inventory of genuine Ratera parts and in-house electronic and mechanical technicians are available by phone or on-site to train, troubleshoot and advise best practice.

Fletcher winders for filament, spun and assembly winds are legendary for their durability and performance. Whether the job needs a light touch for micro-deniers or more stout applications for technical fibers we have a solution to fit your application and budget.

Cassette Winders: Mobile or fixed installation, servo controlled (constant) line speed and package traverse. The solution for technical applications with concerns for delicate fiber handling and the perfect package.

Pirn Winders: Gang machines of 10, 20 or 40 spindles for bobbin spool, double taper or bottle bobbin builds, the Fletcher 20me offers the latest in intuitive operator interface and ease of use and maintenance.

Reeling Systems: Designed for product packaging the FM series of reeling and blocking are autonomous and may be integrated in-line with existing processes. Designed for simplicity the FM makes easy making your products safe for transport and looking good for your customer.

We offer Metag weaving machinery for the efficient manufacture of conveyor belts, sling web, ceramic constructions and other solid woven fabrics. We back all installations with the highest level of customer spares service and technical support.

All machinery projects are reviewed by Metag and Fletcher engineers to assure our customers of the best weaving solution at the best price.

We provide spares support from our extensive inventory of genuine Metag parts and in-house electronic and mechanical technicians are available by phone or on-site to train, troubleshoot and advise best practice.

Our clients are our partners and that means we’re here for you when you need us, from concept to post-installation

We offer Metag weaving machinery for the efficient manufacture of conveyor belts, sling web, ceramic constructions and other solid woven fabrics. We back all installations with the highest level of customer spares service and technical support.

All machinery projects are reviewed by Metag and Fletcher engineers to assure our customers of the best weaving solution at the best price.

We provide spares support from our extensive inventory of genuine Metag parts and in-house electronic and mechanical technicians are available by phone or on-site to train, troubleshoot and advise best practice.

Our clients are our partners and that means we’re here for you when you need us, from concept to post-installation

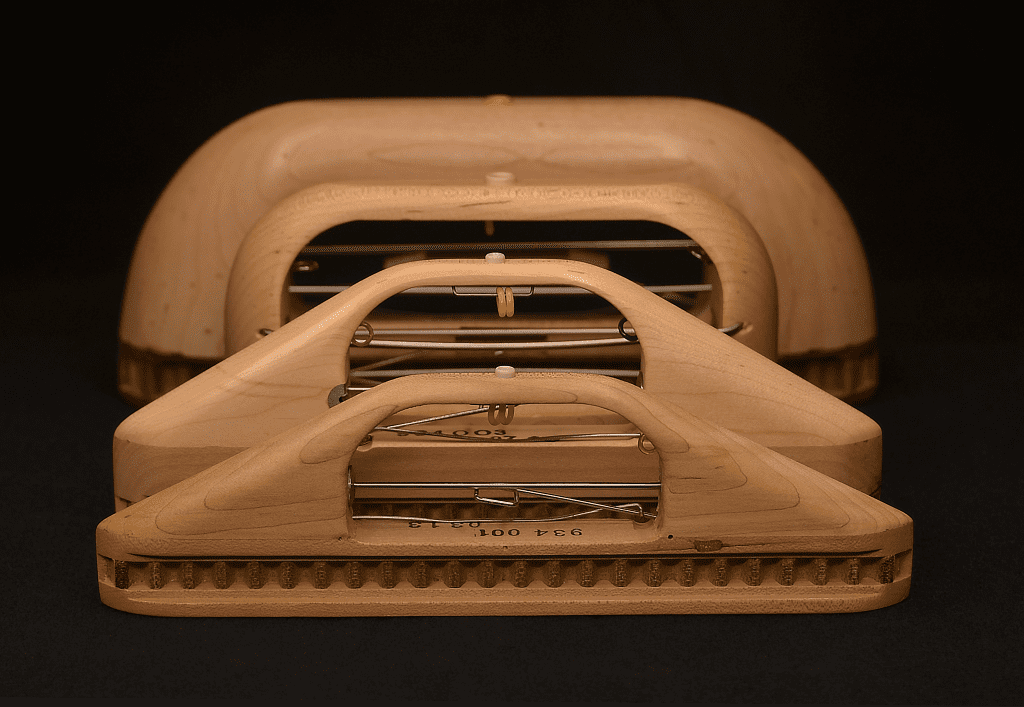

Fletcher offers comprehensive shuttle service for weavers around the word. Broadloom and narrow fabric, apparel to aerospace, Fletcher provides customers with shuttles and accessories designed to meet modern weaving demands.

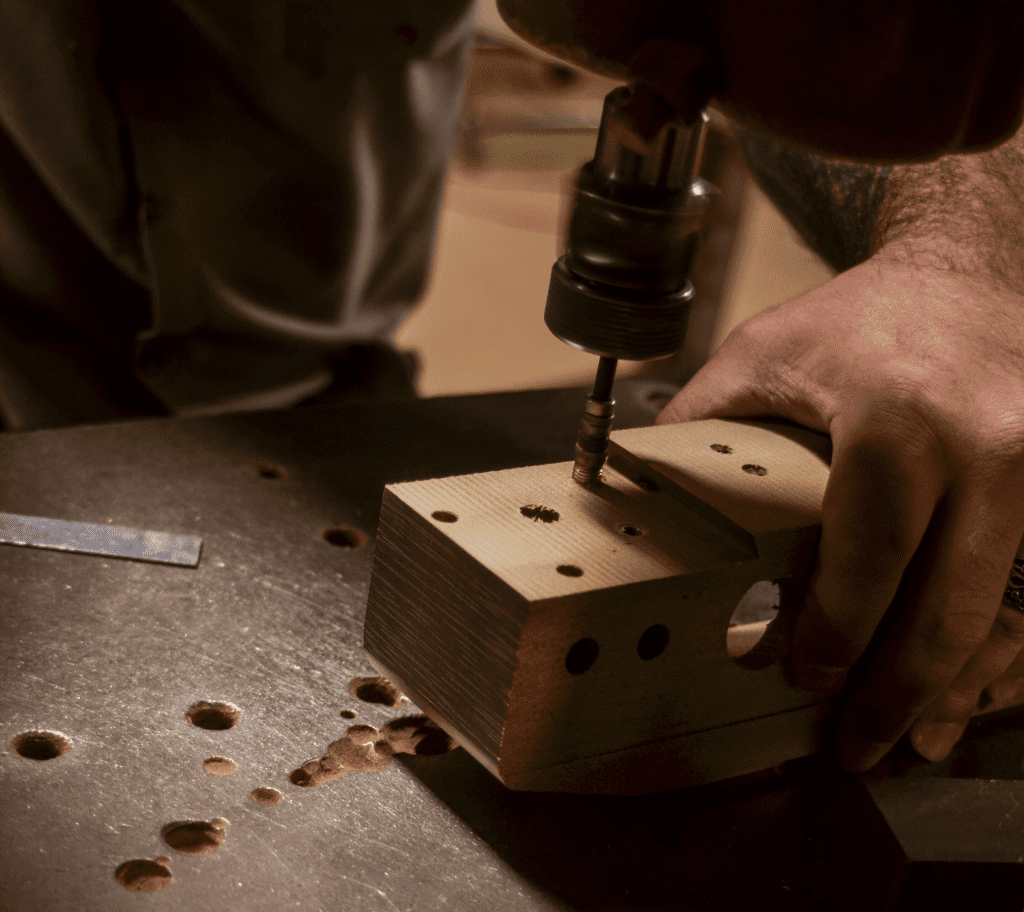

PMC – shuttles for paper machine clothing require engineering, the best material preparation, and skilled execution to achieve an uncompromising result. Fletcher designs and manufactures all components included in our shuttles for total quality performance.

Narrow Fabrics – we make the best shuttles and blocks for narrow width weaving. Whether your space is 26 inches or a fraction of an inch, we have the solution you desire. We serve the aerospace, bio-medical and industrial markets and customize our execution to your specific product and operating environment.